Billie (the belt eater) by Orph Mable

I AM pleased to report also that everyone here at Oxley (Phil, David and myself) are still carrying on and dodging The Reaper for the time being.

I thought I’d come out of hibernation to narrate a short saga of a problem that may be of interest to readers who can recall my series of ‘Yarns from the Yard’.

A short history

Before going into detail, a short history of Nb Billie would paint a picture. This 40ft(ish) narrowboat was purchased by a total novice in late autumn of 2019. His first trip was to collect the boat from the far side of Birmingham and bring it back to Oxley.

He and his partner achieved this feat with only one mishap when a brick jammed the propeller necessitating a call-out for Phil. No mean feat to negotiating the Wolverhampton 21 locks on only the third day of ownership for a complete novice.

The next trip was a short excursion to Brewood on the Shropshire Union (about 90mins each way from Oxley). After a few hours we received a distress call—'the engine had made an awful noise and stopped. Luckily they were only at Bridge 2 and with Phil’s help, pulled the boat back to the yard.

The problems

The totally disconsolate owner was even more distressed when Phil told him that the gear box was loose, drive plate had come adrift, with the fixing bolts jamming the flywheel and putting a hole in the bellhousing! The engine was a very early three cylinder Isuzu with a PRM Delta2 gearbox via a poorly modified bellhousing. I sat down with owner and explained the issues. He asked if we could help him get out of the fix . It was agreed that over the winter we would purchase and fit a new Canaline 25 engine plus carry out many internal and external changes to the boat with the target of Easter 2020 to be ready for use.

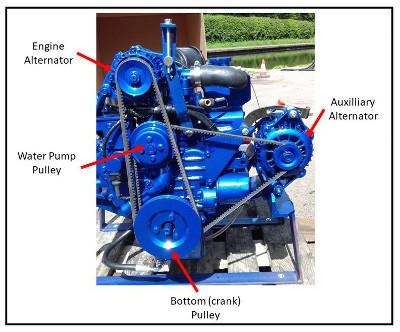

All was agreed. To cut a very long and complex story short, we removed the old engine, completely gutted and painted the engine compartment then fitted the brand new Canaline 25 engine (shown) and propeller. (The existing one was slightly bent due to the brick incident.)

All was agreed. To cut a very long and complex story short, we removed the old engine, completely gutted and painted the engine compartment then fitted the brand new Canaline 25 engine (shown) and propeller. (The existing one was slightly bent due to the brick incident.)

Then the rains came

Then the rains came! Virtually all outside work ceased for nearly three months but David was able to completely redesign the interior and refit to meet the customer wish list.

With the arrival of March 2020, the Coronavirus and the better weather, David was able to complete the outside welding and fabricating to produce a new slide hatch, gas locker top and lid plus stowage boxes/seats in the semi-trad stern. Also Phil could start testing the engine (When David would let him). The owner was also able to have a short ride to demonstrate our achievements.

Not contravening

As an aside it is worth pointing out to everyone that we all, Phil, David and I, live here in the boatyard so are not contravening the Government Guidelines and were working ‘from home’. Also providing essential diesel, gas and coal for many residential boaters in this area plus essential and urgent repairs as necessary.

Having given some background I will get back on track with the focus of this article. With all the internal work being almost completed and the external fabrication stuff completed, Phil wanted to do a few checks, tests and the 50 hour service on the engine. 50 hours I hear you say. Yes! David needed 12volt power for lights and pumps etc. whilst working on the cabin fit-out (also the heating stove during December to February—but that is another story) so it had been run a fair amount. David also reported that the engine was ‘squealing’ when first started in a morning.

Before starting the service, it is Phil’s routine to carry out a visible check so immediately noticed that the drive belt to the auxiliary alternator (domestic charging) was badly worn, plus there were signs of the engine alternator belt rubbing on the water pump pulley. This is beginning to sound complicated but fear not, I will attempt to explain.

Before starting the service, it is Phil’s routine to carry out a visible check so immediately noticed that the drive belt to the auxiliary alternator (domestic charging) was badly worn, plus there were signs of the engine alternator belt rubbing on the water pump pulley. This is beginning to sound complicated but fear not, I will attempt to explain.

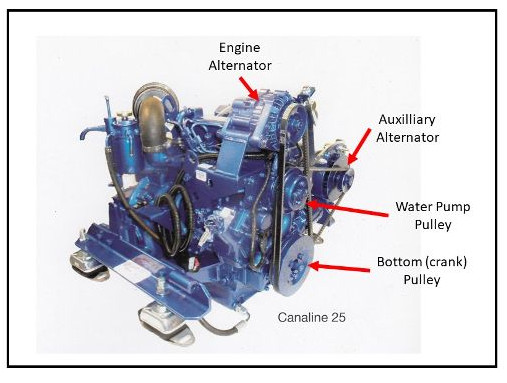

The Canaline 25

The Canaline 25 Engine is a small three cylinder 25 horse power motor, manufactured in South Korea, imported and marinised by Engines Plus. It is a robust unit with ample power to drive narrowboats up to 45 foot comfortably. As supplied by Engines Plus it comes with two alternators, one supplying up to 50 amps @ 12volts to charge the engine battery and another larger auxiliary alternator, supplying up to 100 amps @ 12 volts to the domestic batteries.

Canaline 25 engine as supplied by Engines Plus. This tidy compact unit is ideal to shoe-horn into what is usually a small space on a short boat and was the 4th one that we’ve fitted over the last couple of years. That said, small boats are not that popular and only a relatively low number of units have been produced.

Canaline 25 engine as supplied by Engines Plus. This tidy compact unit is ideal to shoe-horn into what is usually a small space on a short boat and was the 4th one that we’ve fitted over the last couple of years. That said, small boats are not that popular and only a relatively low number of units have been produced.

The problem

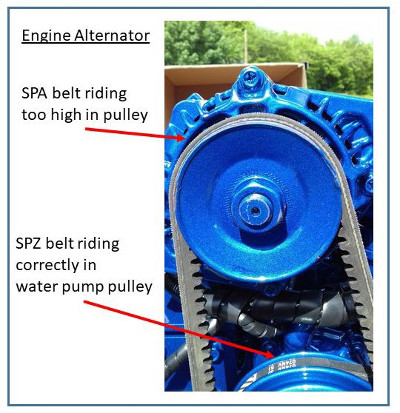

The three pictures are from a set that were sent to Engines Plus in 2018 to discuss what Phil thought would possibly cause a problem when the engine was used. We were thanked and told it would be addressed.

Looking at the picture at first glance this appears to be a well thought out marinised engine. However, looking more carefully you may note what Phil saw.

Two alternators

There are two alternators, the engine and auxiliary, driven by the double pulley on the engine crank . So far so good! First thing to note is the two different drive belt types—not unusual in itself.

The auxiliary alternator and water pump is driven by an SPZ (9mm wide) type. The engine alternator is driven by an SPA (12mm wide) type. Now the load on the heavier belt is 50 amps (max) whilst the thinner belt is driving the water pump and a 90 amp (max) alternator (illogical methinks). But it gets worse:

The auxiliary alternator and water pump is driven by an SPZ (9mm wide) type. The engine alternator is driven by an SPA (12mm wide) type. Now the load on the heavier belt is 50 amps (max) whilst the thinner belt is driving the water pump and a 90 amp (max) alternator (illogical methinks). But it gets worse:

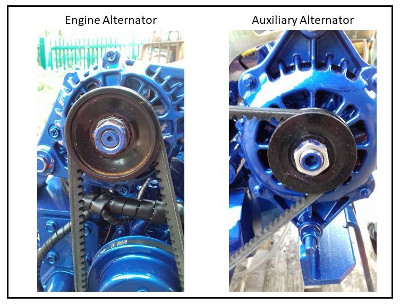

When studying the auxiliary alternator pulley, it can be seen that the belt rides too low which could wear the belt causing it to move into the pulley as it wears, increasing the wear and so on.

On the auxiliary alternator, the SPA belt rides too high, again causing uneven wear. The SPZ belt driving the water pump sits correctly.

Nothing has changed

As I said earlier this problem was spotted by Phil in early 2018, but despite us passing the facts to Engines Plus nothing has changed on the last three Canaline 25s that we have received.

Phil could not see the problem go without trying to do something about it, whilst being careful not to affect any warranty present on the new engines. His ‘quick fix’ was to replace those pulleys where he could. However other Canaline 25 users are still complaining that the SPZ belt on the auxiliary alternator/water pump does not last 100 hours. This ‘fix’ can be seen on earlier pictures.

Not only is the SPZ wearing fast but the SPA is rubbing on the water pump occasionally, especially with the vibration at start up. Why would we persist with this engine?—because the core engine is basically so good.

Not only is the SPZ wearing fast but the SPA is rubbing on the water pump occasionally, especially with the vibration at start up. Why would we persist with this engine?—because the core engine is basically so good.

Readers will wonder how a new engine could be like this. My thoughts are quite clear on the subject.

The problem developing

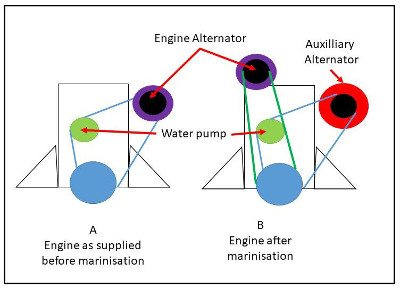

In the very rough diagram I have sketched (below) out two symbolic engines. Engine A shows the position of the standard Kioti 25 industrial engine as sent out from the Korean factory. This engine is used to power plant (mini-diggers, dumper trucks etc). You’ll note that it only has a single alternator also all pulleys are SPZ size and is only fitted with a single SPZ bottom pulley.

Engine B shows the changed layout after marinisation by Engines Pls. There is now a double bottom pulley with an SPA & SPZ track. The engine alternator has moved too high on the starboard side of the engine and a new auxiliary alternator fitted to the port side. Good in theory but not so in practice.

Engine B shows the changed layout after marinisation by Engines Pls. There is now a double bottom pulley with an SPA & SPZ track. The engine alternator has moved too high on the starboard side of the engine and a new auxiliary alternator fitted to the port side. Good in theory but not so in practice.

The auxiliary alternator has an SPA pulley fitted, the water pump and bottom pulley are SPZ! The Engine alternator is fitted with an SPZ pulley and is driven by an SPA belt and bottom pulley. Another problem is the closeness of the SPA drive belt to the water pump. Hence our problem:

Billie

Back to the issue with Nb Billie. Here the engine had been installed and other than putting up with the regular changing of SPZ belts (every 50 hours?) what could we do?

Phil, David and I sat down with plenty of tea and mulled over the way forward (you can’t rush our thought processes, we are all getting on a bit). To minimise labour costs we did not want to remove the engine from the boat if at all possible. It had to be a ‘proper fix’ and not just extend the life of belts by another few hours and we had to be able to do it in-house due to the lock-down rules. Phil’s solution was the one that we decided to try as he thought it met the criteria stated. I was a sceptical that it could be done without removing the engine but was assured that it could be done.

The Plan

The Plan

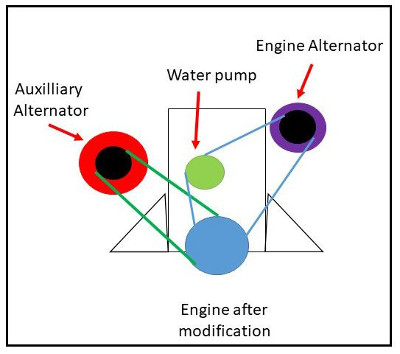

In theory it sounds simple enough, just swap the two alternators around as shown in the diagram.

With the engine alternator back where the original manufacturer put it using the SPZ belt to drive the water pump and small alternator the only alterations would be to extend the four wires an extra 12 inches or so everything else would fit.

The 100 amp heavier alternator was a bit more taxing. It couldn’t sit high up on the engine as it would foul the deck boards. Too low and close to the engine and it would foul the throttle controls. Undaunted, Phil fabricated a 3 inch extension to the original port side alternator bracket from steel and modified the adjuster to be fixed onto the port side front engine mount. Everything was completed in a single day including spraying the new metalwork in matching blue paint.

The final proof of our success will show if we finally get prolonged belt life but with the finished modifications there does not appear to be any wear after several ‘test hours’. An added bonus the original belt sizes, SPA & SPZ still fit this engine so no unusual belts have to be kept in stock. All we need now is continuing good weather and the lock-down to be lifted so the owner can take Nb Billie for an extended cruise.